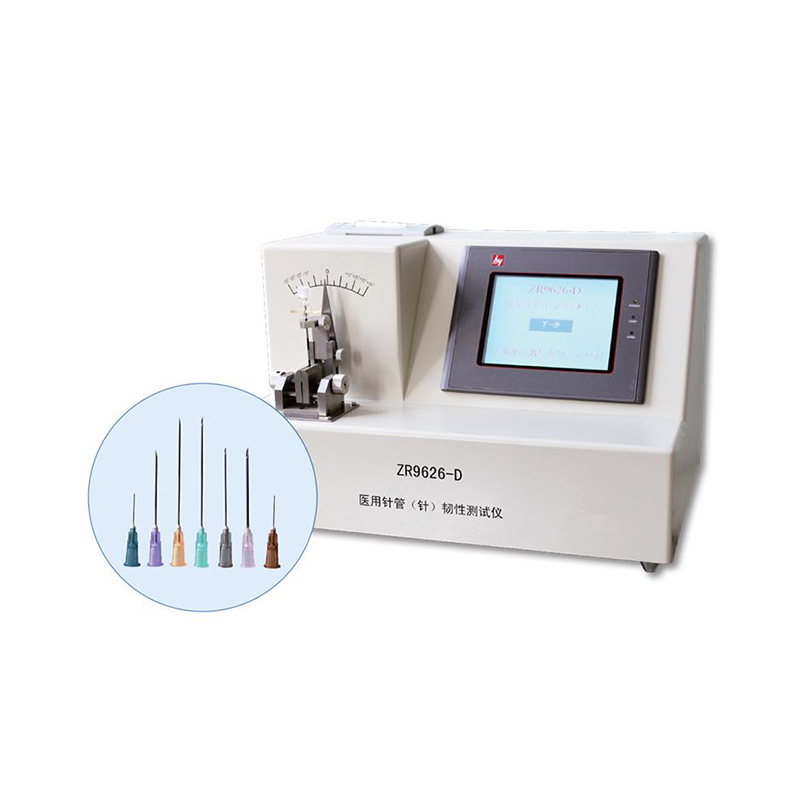

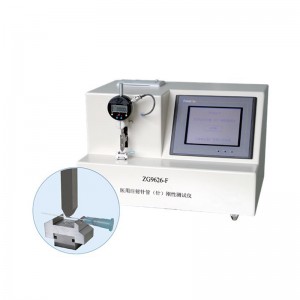

ZR9626-D Medical Needle ( Tubing ) Resistance Breakage Tester

These tests are crucial to ensuring the reliability and safety of medical needles during use. Tensile Strength Testing: Tensile strength testing involves applying a pulling force to the needle until it reaches the point of failure or breakage. This test helps determine the maximum force the needle can withstand before breaking. Bend Test: The bend test involves applying a controlled bending force on the needle to evaluate its flexibility and resistance to bending without breaking. It helps assess the needle's ability to withstand stress during medical procedures. Needle Puncture Test: This test assesses the needle's ability to penetrate and pierce a material, such as skin or tissue simulants, accurately and without breaking. It helps evaluate the sharpness and durability of the needle tip. Compression Test: The compression test involves applying pressure to the needle to assess its resistance to deformation under compressive forces. It helps determine the needle's ability to maintain its shape and integrity during use. These testing methods are usually performed using specialized equipment, including universal testing machines, force gauges, or custom-designed fixtures depending on the specific test requirements. It is important to note that different standards and regulations may dictate specific testing requirements for medical needles, and manufacturers should follow these guidelines to ensure compliance and safety.