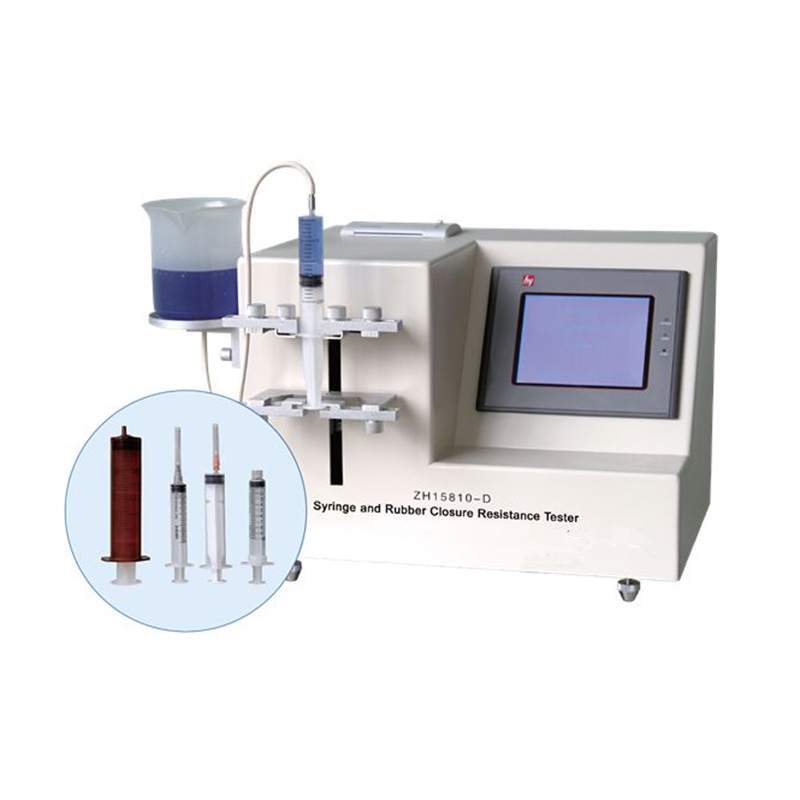

ZH15810-D Medical Syringe Sliding Tester

A medical syringe sliding tester is a device used to test the smoothness and ease of movement of the plunger within a syringe barrel. It is an important tool in the quality control process for syringe manufacturing to ensure that the syringes function properly and do not have any defects affecting their sliding action.The tester typically consists of a fixture or holder that securely holds the syringe barrel in place, and a mechanism to apply controlled and consistent pressure to the plunger. The plunger is then moved back and forth within the barrel while measurements are taken to assess the sliding performance.The measurements can include parameters such as the force required to move the plunger, the distance traveled, and the smoothness of the sliding action. The tester may have built-in force sensors, position detectors, or displacement sensors to accurately capture and quantify these parameters.Manufacturers can use the sliding tester to evaluate the frictional properties of the syringe components, such as the plunger surface, barrel inner surface, and any lubrication applied. The results obtained from the sliding test can help identify any sticking, binding, or excessive force required during the sliding action, which could affect the syringe's functionality.By analyzing and optimizing the sliding performance, manufacturers can ensure that the syringes provide smooth and reliable operation, reducing the risk of any discomfort or difficulty in use for healthcare professionals and patients.It's worth mentioning that specific testing requirements and standards for syringe sliding performance may vary depending on the regulatory guidelines or industry standards followed in a particular region or country. Manufacturers should adhere to these guidelines to ensure compliance and produce high-quality syringes.