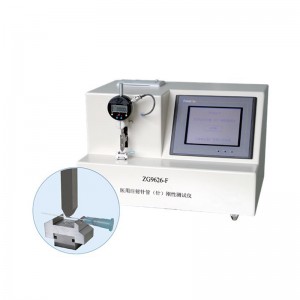

ZG9626-F Medical Needle ( Tubing ) Stiffness Tester

A medical needle stiffness tester is a specialized device used to measure the stiffness or rigidity of medical needles. It is designed to evaluate the flexibility and bending properties of needles, which can impact their performance during medical procedures.The tester typically consists of a setup where the needle is placed and a measurement system that quantifies the stiffness of the needle. The needle is usually mounted vertically or horizontally, and a controlled force or weight is applied to induce bending.The stiffness of the needle can be measured in various units, such as Newton/mm or gram-force/mm. The tester provides precise measurements, allowing manufacturers to assess the mechanical characteristics of medical needles accurately.Key features of a medical needle stiffness tester may include:Adjustable Load Range: The tester should be capable of applying a wide range of forces or weights to accommodate different-sized needles and assess their flexibility.Measurement Accuracy: It should provide accurate measurements of the stiffness of the needle, allowing for comparison and analysis.Control and Data Collection: The tester should have user-friendly controls for setting up the test parameters and capturing test data. It may also come with software for data analysis and reporting.Compliance with Standards: The tester should adhere to relevant industry standards, such as ISO 7863, which specifies the test method for the determination of the stiffness of medical needles.Safety Measures: Safety mechanisms should be in place to prevent any potential injuries or accidents during testing.Overall, a medical needle stiffness tester is an essential tool for evaluating the mechanical characteristics and quality of medical needles. It helps manufacturers ensure their needles meet the required stiffness specifications, which can influence their performance and patient comfort during medical procedures.