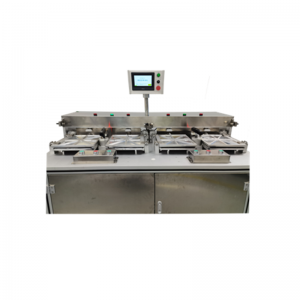

ZF15810-D Medical Syringe Air Leakage Tester

A medical syringe air leakage tester is a device used to test the air-tightness or leakage of syringes. This testing is crucial in the quality control process of syringe manufacturing to ensure that they are functioning properly and free from any defects.The tester works by creating a controlled pressure difference between the inside and outside of the syringe barrel. The syringe is connected to the tester, and air pressure is applied to the inside of the barrel while the outside is maintained at atmospheric pressure. The tester measures the pressure difference or any air leakage occurring from the syringe barrel.There are different types of syringe air leakage testers available, and they can vary in design and functionality. Some may have built-in pressure regulators, gauges, or sensors to accurately measure and display the pressure or leakage results. The testing procedure may involve manual or automated operations, depending on the specific tester model.During the test, the syringe may be subject to different conditions such as varying pressure levels, sustained pressure, or pressure decay tests. These conditions simulate real-world usage scenarios and help identify any potential leakage issues that could compromise the syringe's functionality or integrity.By conducting air leakage tests using dedicated testers, manufacturers can ensure that their syringes meet the required standards and specifications, providing reliable and safe medical devices for healthcare professionals and patients.It's important to note that specific testing requirements and standards for syringes may vary depending on the country or regulatory bodies governing medical device manufacturing. Manufacturers should follow these guidelines to ensure compliance and produce high-quality syringes.