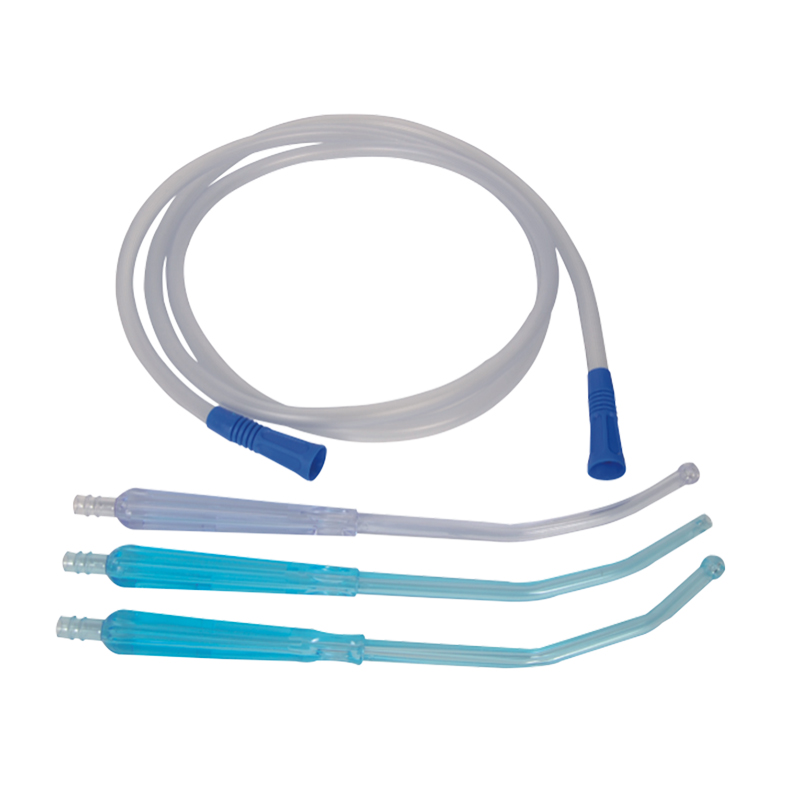

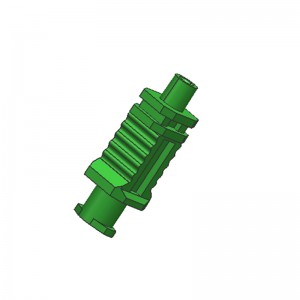

A Yankauer handle mold is a specialized tool used in the manufacturing process of Yankauer handles. A Yankauer handle is a medical device used during suction procedures to remove fluids or debris from a patient's body. The mold is used to produce the handle component of the Yankauer suction device.Here are some key aspects of how a Yankauer handle mold works:Mold Design: The mold for a Yankauer handle is designed to create the specific shape and features required for the handle component. It typically consists of two halves that fit together, forming a cavity for the molten material to be injected into. The mold is usually made from durable materials, such as steel or aluminum, to withstand the high pressures and temperatures involved in the molding process.Material Injection: Once the mold is set up, a thermoplastic material, such as PVC or polypropylene, is heated until it becomes molten. The molten material is then injected into the mold cavity using high-pressure injection molding machines. The material flows through channels and gates within the mold, filling the cavity and taking the shape of the Yankauer handle component. The injection process is controlled and precise to ensure consistent and accurate production of the handles.Cooling, Solidification, and Ejection: After the material is injected, it cools and solidifies within the mold. Cooling can be achieved through cooling channels integrated into the mold or by moving the mold into a cooling chamber. Once the material has solidified, the mold is opened, and the finished Yankauer handle is ejected. Ejection mechanisms, such as ejector pins or air pressure, are used to safely and efficiently remove the handle from the mold.Quality control measures are typically implemented throughout the manufacturing process to ensure the Yankauer handles meet the required specifications and adhere to medical standards. This includes inspecting the mold design, monitoring the injection parameters, and conducting post-production inspections of the finished handles to ensure their quality, functionality, and safety.Overall, a Yankauer handle mold enables the efficient and precise production of Yankauer handles, which are vital medical devices used in suction procedures. The mold ensures the handles are consistently produced to the required specifications, meet medical standards, and provide reliable performance during suction procedures.