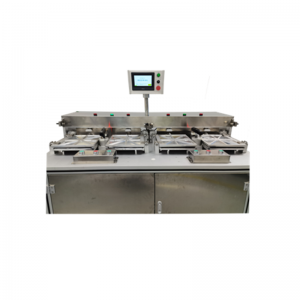

WM-0613 Plastic Container Burst and Seal Strength Tester

A plastic container burst and seal strength tester is a device designed specifically to measure the burst strength and seal integrity of plastic containers. These containers can include bottles, jars, cans, or any other type of plastic packaging used for storing or transporting various products.The testing process for a plastic container burst and seal strength tester typically involves the following steps:Preparing the sample: Fill the plastic container with a specified amount of liquid or pressure medium, ensuring it is properly sealed.Placing the sample in the tester: Position the sealed plastic container securely within the burst and seal strength tester. This can be achieved by using clamps or fixtures designed to hold the container in place.Applying pressure: The tester applies increasing pressure or force to the container until it bursts. This test determines the maximum burst strength of the container, providing an indication of its ability to withstand internal pressure without leaking or failing.Analyzing the results: The tester records the maximum pressure or force applied before the container bursts. This measurement indicates the burst strength of the plastic container and determines if it meets the specified requirements. It also helps assess the quality and durability of the container.To test the seal strength of the container, the process is slightly different:Preparing the sample: Fill the plastic container with a specified amount of liquid or pressure medium, ensuring it is properly sealed.Placing the sample in the tester: Position the sealed plastic container securely within the seal strength tester. This may involve fixing the container in place using clamps or fixtures.Applying force: The tester applies a controlled force to the sealed area of the container, either by pulling it apart or exerting pressure on the seal itself. This force simulates the stresses the container may experience during normal handling or transportation.Analyzing the results: The tester measures the force required to separate or break the seal and records the result. This measurement indicates the seal strength and determines if it meets the specified requirements. It also helps assess the quality and effectiveness of the container's seal.The instructions for operating a plastic container burst and seal strength tester may vary depending on the manufacturer and model. It is important to refer to the user manual or guidelines provided by the manufacturer for accurate testing procedures and interpretation of results.By using a plastic container burst and seal strength tester, manufacturers and packaging companies can ensure the quality and integrity of their plastic containers. This is particularly important for products that require leak-proof or pressure-resistant packaging, such as beverages, chemicals, or hazardous materials.