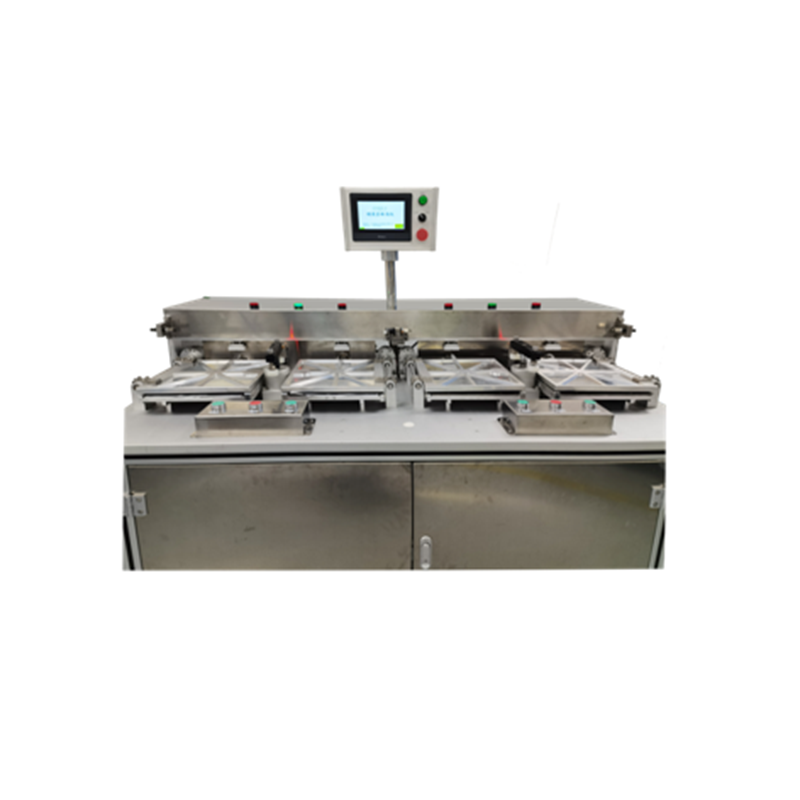

Waste Liquid Bag Leakage Detector

The instrument uses a high-precision differential pressure sensor to detect the air tightness of the product through the pressure change of the two products. Manual loading and unloading and automatic detection are realized through the interface of actuator and pipe fixture. The above control is controlled by PLC and displayed by touch screen.

The peristaltic pump is used to extract constant temperature 37℃ water from the water bath, which passes through the pressure regulating mechanism, pressure sensor, external detection pipeline, high-precision flowmeter, and then back to the water bath.

The normal and negative pressure states are controlled by the pressure regulating mechanism. The sequential flow rate in the line and the accumulated flow rate per unit time can be precisely measured by the flowmeter and displayed on the touch screen.

The above control is controlled by PLC and servo peristaltic pump, and the detection accuracy can be controlled within 0.5%.

PRESSURE SOURCE: Detect the air input source; F1: Air filter; V1: Precision pressure reducing valve; P1: Detecting pressure sensor; AV1: Air control valve (for inflation); DPS: High precision differential pressure sensor; AV2: Air control valve (exhaust); MASTER: standard reference terminal (negative terminal); S1: exhaust muffler; WORK: product detection end (positive end); Products 1 and 2: connected products of the same type being tested; PILOT PRESSURE: Drive air input source; F4: Integrated filter pressure reducing valve; SV1: solenoid valve; SV2: solenoid valve; DL1: inflation delay time; CHG: inflation time; DL2: Balance delay time: BAL balance time; DET: detection time; DL3: exhaust and blow time; END: time of finishing and discharging;

6.Please pay attention when using

(1) The instrument should be placed smoothly and away from the vibration source, so as not to affect the measurement accuracy;

(2) Use in a safe environment, away from flammable and explosive materials;

(3) Do not touch and move the test items during the test, so as not to affect the measurement accuracy;

(4) The instrument for gas pressure detection of airtight performance, to ensure the access of air pressure stability and clean air. So as not to damage the instrument.

(5) After starting up every day, wait 10 minutes for detection

(6) Check whether the pressure exceeds the standard before detection to prevent the explosion of excessive pressure!

A waste liquid bag leakage detector is a specialized device used to detect and monitor any leakage or breaches in waste liquid bags or containers. It helps to prevent environmental contamination and ensure the safe handling and disposal of waste liquids.Here's how a waste liquid bag leakage detector typically works:Installation: The detector is placed in proximity to the waste liquid bags or containers, such as in a containment area or near the storage tanks. It is usually equipped with sensors or probes that can detect leaks or breaches in the bags or containers.Leakage detection: The detector continuously monitors the waste liquid bags or containers for any signs of leakage. This can be done through various methods, such as pressure sensors, visual inspection, or chemical sensors that can detect specific substances in the waste liquid.Alarm system: If a leak or breach is detected, the detector triggers an alarm system to alert the operators or personnel responsible for handling the waste liquid. This allows for immediate action to be taken to address the leakage and prevent further contamination.Data logging and reporting: The detector may also have a data logging feature that records the time and location of any detected leaks or breaches. This information can be used for reporting purposes, maintenance records, or compliance with regulations and standards.Maintenance and calibration: Periodic maintenance and calibration of the detector are essential to ensure accurate and reliable leakage detection. This may involve checking the sensors, replacing batteries, or calibrating the device to maintain its effectiveness.A waste liquid bag leakage detector is a crucial tool in industries where the proper handling and disposal of waste liquids are essential, such as chemical plants, wastewater treatment facilities, or medical facilities. By promptly detecting and addressing leaks or breaches, it helps to prevent environmental contamination, protect personnel, and ensure compliance with regulations and safety standards.