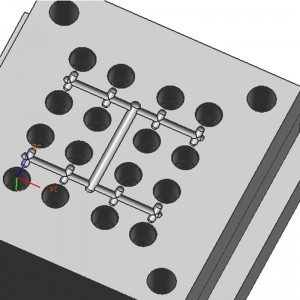

Venturi Mask plastic injection mold/mould

The Venturi mask is a medical device used to deliver a high flow of oxygen to patients with respiratory difficulties. It consists of a mask, tubing, and a Venturi valve.The Venturi valve has different size orifices that create specific flow rates of oxygen. This allows the healthcare provider to adjust the concentration of oxygen delivered to the patient accurately.The Venturi mask is primarily used in cases where precise oxygen concentrations are required, such as in patients with chronic obstructive pulmonary disease (COPD), asthma, or other respiratory conditions. It is especially useful in patients who need a controlled and predictable oxygen concentration, as it delivers a specific fraction of inspired oxygen (FiO2).To use a Venturi mask, the appropriate orifice is selected based on the desired oxygen concentration. The tubing is then connected to a source of oxygen, and the mask is placed over the patient's nose and mouth. The mask should fit snugly to ensure optimal oxygen delivery.It's essential to monitor the patient's oxygen saturation levels and adjust the orifice as needed to maintain the desired FiO2. Additionally, regular assessment of the patient's respiratory status and adjustment of the oxygen flow rate may be necessary.The Venturi mask is generally safe and effective when used correctly under healthcare provider supervision. It allows for precise oxygen delivery, making it a valuable tool in managing respiratory conditions.

|

1.R&D |

We receive customer 3D drawing or sample with details requirements |

|

2.Negotiation |

Confirm with clients details about: the cavity, runner, quality, price, material, delivery time, payment item, etc. |

|

3.Place an order |

According your clients design or chooses our suggestion design. |

|

4. Mould |

First We send mould design to customer approval before We make the mould and then start production. |

|

5. Sample |

If the first sample come out is not satisfied customer, we modify the mould and until meet customers satisfactory. |

|

6. Delivery time |

35~45days |

|

Machine Name |

Quantity ( pcs ) |

The original country |

|

CNC |

5 |

Japan/Taiwan |

|

EDM |

6 |

Japan/China |

|

EDM ( Mirror) |

2 |

Japan |

|

Wire Cutting ( fast ) |

8 |

China |

|

Wire Cutting ( Middle ) |

1 |

China |

|

Wire Cutting ( slow ) |

3 |

Japan |

|

Grinding |

5 |

China |

|

Drilling |

10 |

China |

|

Lather |

3 |

China |

|

Milling |

2 |

China |