UV Curving Machine for Medical Use

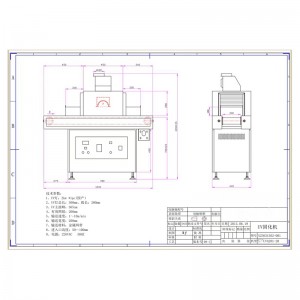

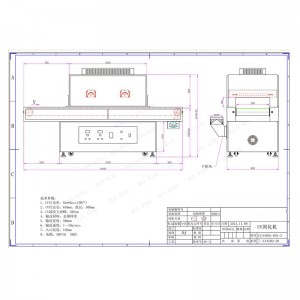

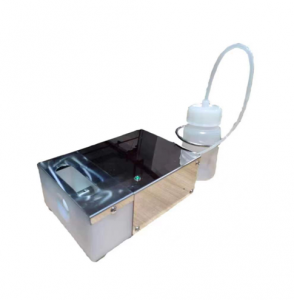

A UV curving machine is a specialized piece of equipment used to bend and shape materials using ultraviolet (UV) light. This technology is commonly used in industries like automotive, aerospace, electronics, and signage to shape materials such as plastics, polymers, and composites.The UV curving machine typically consists of the following components:UV Light Source: This is the main component of the machine that emits high-intensity UV light. It is usually a specialized UV lamp or LED array that emits the required wavelength for curing the material.Curving Bed: The curving bed is the platform where the material to be curved is placed. It is often made of a heat-resistant material and may have adjustable features like clamps or fixtures to hold the material securely during the curving process.Light Guide or Optics System: In some UV curving machines, a light guide or optics system is used to direct and focus the UV light onto the material. This ensures precise and controlled exposure to the UV light during the curving process.Control System: The machine is typically equipped with a control system that allows the operator to set and adjust various parameters such as the intensity and duration of the UV light exposure. This enables customization and control over the curving process to achieve desired results.The UV curving process involves placing the material onto the curving bed and positioning it in the desired shape or form. The UV light is then directed onto the material, causing it to soften or become pliable. The material is then gradually bent and curved into the desired shape using molds, fixtures, or other tools as necessary.Once the material is in the desired shape, the UV light is turned off, and the material is allowed to cool and solidify, locking it in the curved shape. The UV light helps to cure and harden the material efficiently and quickly, reducing the processing time and ensuring a strong and durable end product.UV curving machines are versatile and can be used for a wide range of applications. They offer advantages such as precise control over the curving process, faster curing times, and the ability to work with a variety of materials.