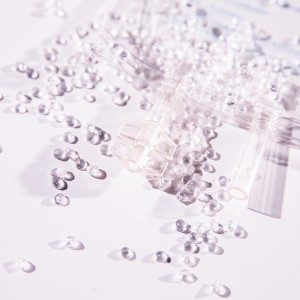

Medical Grade Compounds Rigid PVC Series

|

Model |

MT50S |

|

Appearance |

Transparent |

|

Hardness(ShoreA/D) |

50-80D |

|

Tensile strength(Mpa) |

/ |

|

Elongation,% |

/ |

|

180℃Heat Stability (Min) |

≥60 |

|

Reductive Material |

≤0.3 |

|

PH |

≤1.0 |

Rigid PVC Series PVC Compounds refer to a range of specialized formulations of polyvinyl chloride (PVC) that are specifically designed for the production of rigid or semi-rigid plastic products. These compounds are widely used in various industries, including construction, electrical, automotive, and consumer goods.Rigid PVC compounds offer several key features and benefits:Stiffness and Strength: Rigid PVC compounds have excellent stiffness and mechanical strength, making them ideal for applications that require structural integrity and durability. They can withstand heavy loads, impacts, and weathering without deformation or failure.Chemical Resistance: These compounds exhibit high resistance to chemicals, such as acids, alkalis, and oils. This makes them suitable for applications where the PVC product may come into contact with corrosive substances.Flame Retardant Properties: Rigid PVC compounds can be formulated to have excellent flame retardant properties. This makes them suitable for applications that require products to meet strict fire safety standards.Electrical Insulation: Rigid PVC compounds have good electrical insulating properties, making them suitable for various electrical applications, such as cable and wire insulation, electrical conduit pipes, and electrical fittings.Processability: Rigid PVC compounds are easy to process using common techniques like extrusion, injection molding, and blow molding. They have good flow properties, allowing for efficient and consistent production of complex shapes and designs.Wide Range of Applications: Rigid PVC compounds are used in a wide range of applications including pipes and fittings, window profiles, decking, cladding, automotive parts, toys, and consumer packaging.Overall, Rigid PVC Series PVC Compounds offer a combination of mechanical, chemical, and electrical properties that make them ideal for producing robust and durable rigid plastic products. Their versatility, processability, and wide range of applications make them a popular choice in various industries.