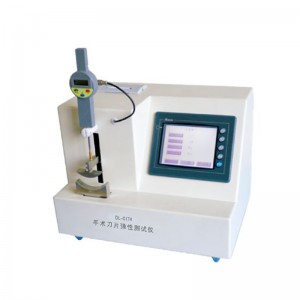

Pump Line Performance Detector

This device is composed of water bath box, high precision linear step control pressure regulator, pressure sensor, high precision flow meter, PLC control module, automatic following servo peristaltic pump, immersion temperature sensor, switching power supply and so on.

A temperature and humidity sensor is installed outside the device to measure the ambient temperature and humidity.

The peristaltic pump is used to extract constant temperature 37℃ water from the water bath, which passes through the pressure regulating mechanism, pressure sensor, external detection pipeline, high-precision flowmeter, and then back to the water bath.

The normal and negative pressure states are controlled by the pressure regulating mechanism. The sequential flow rate in the line and the accumulated flow rate per unit time can be precisely measured by the flowmeter and displayed on the touch screen.

The above control is controlled by PLC and servo peristaltic pump, and the detection accuracy can be controlled within 0.5%.

(1) The device has a good man-machine interface, all kinds of operation commands can be completed with a touch of the hand, and the display screen prompts the user to operate;

(2) Water bath automatic temperature control function, can maintain a constant temperature, the water level is too low will automatically alarm;

(3) The device is equipped with a cooling fan, which effectively prevents the PLC data transmission from being affected by the high temperature in the machine;

(4) servo peristaltic pump, can accurately locate each step of the action, so that the water intake can be accurately controlled;

(5) Water connected with high-precision mass flowmeter, accurate detection of instantaneous flow and cumulative flow per unit time;

(6) The pipeline pumps water from the water bath and back to the water bath to ensure the recycling of water and reduce waste;

(7) Real-time detection and display of ambient temperature and humidity, real-time detection and display of liquid temperature in the pipeline;

(8) Real-time sampling and detection of traffic data and presented in the form of trend curve on the touch screen;

(9) The data can be read in real time through the form of networking, and the configuration software report file is displayed and printed.

A pump line performance detector is a device used to monitor and measure the performance and efficiency of pump systems. It helps to ensure that pumps are operating optimally and can detect any potential issues or failures in the pump line.Here's how a pump line performance detector typically works:Installation: The detector is connected to the pump system, usually by attaching it to a fitting or pipe in the pump line. It may require the use of adapters or connectors to ensure a secure connection.Measurement and monitoring: The detector measures various parameters related to the pump's performance, such as flow rate, pressure, temperature, and vibration. This data is continuously monitored and analyzed by the device.Performance analysis: The detector analyzes the collected data to determine the overall efficiency of the pump system. It can identify any deviations from normal operating conditions and provide valuable insights into the performance of the pump.Alerts and warnings: If the detector detects any abnormalities or potential issues, it can generate alerts or warnings. These notifications can help prompt maintenance or repair actions to prevent further damage or failures.Diagnostics and troubleshooting: In case of a pump system failure or inefficiency, the detector can assist in diagnosing the root cause of the problem. By analyzing the collected data, it can identify specific areas in the pump line that may require attention, such as clogged filters, worn-out bearings, or leaks.Maintenance and optimization: The detector can also provide recommendations for maintenance or optimization of the pump system. This could include suggestions for cleaning, lubrication, replacement of worn-out components, or adjustments to the pump's settings.By using a pump line performance detector, operators and maintenance personnel can proactively monitor and manage the performance of pump systems. This helps to prevent unexpected failures, reduce downtime, and optimize the efficiency of pumps. Regular monitoring and analysis with a pump line performance detector can contribute to overall cost savings, energy efficiency, and improved reliability of pump systems.