-

Ultrosonic Plastic Welding Machine for Shell

Power: 15KHZ or 20HZ

Frequency: 4200W or 2000w

Air Pressure: 0.1-1.0MPA

Input Voltage: AC220V-240V

Welding Travel Distance: 75mm

Machine Size: 750mm*900mm*1950mm or 400mm*600mm*1050mm

Generator Size: 280*110*370mm or

Output Time: 0.01-9.99s

Welding Mode: time/energy/time+energy

Intelligent Management: Amplitude/Quality/Data/Safety Management

Machine Weight: 130KGS or 75KGS

Rack: round column

Work Mode: Button/External Control

Generator Electric Circuit: Digital intelligent automatic frequency chasing

Control System: 485 communication

Lanaguage: English/Chinese

Safety Management: password protect

Operation Interface: 4.3’’ external touch screen

Driving Mode: Pneumatic -

Corrugated Tube Machine for Medical Products

Corrugated Pipe Production Line has adopted chain connection mould, which is convenient for disassembly and the length of product can be adjustable. It is stable operation with the fast production rate up to 12 meters per minute, has very high performance-price ratio.

This production line is suitable for such production as automobile wire harness tube, electric wire conduit, washing machine tube, air-condition tube, extension tube, medical breathing tube and various other hollow moulding tubular products etc.

-

Plastic Heating Oven Machine for Efficient Heating

1– Product introduction

The precision temperature controller is used to control the heating system to realize temperature equalization test and drying heat treatment. The equipment is suitable for high-tech electronics industry, scientific research institutions, schools, factories, laboratories and other units. Oven inner liner is made of galvanized sheet, stainless steel sheet, cold rolled sheet, cold rolled sheet, full touch panel, microcomputer PID and SSR control, LED double digital display, LED digital display timer, independent overtemperature protection, self-diagnosis function. -

UV Curving Machine for Medical Use

Specification:

Lamp: 2kw*1pc or 5kw*2PC

Lamp Length: 300mm or 630mm; Arc length:200mm or 500mm

Major crest: 365nm

Effective irradiation:200mm

Speed: 1~10m/min

Width:200mm or 500mm

Entrance height: 50~100mm or 150mm

Power: 220V 50HZ or 380V 50HZ -

Standard Dry Machine for Medical Use

Specification:

Save Time, Save Manpower, Tube on the base isolation type design, easy to clean material. Simple and rapid refueling. A, L type tripod, hot air recovery device, Exhaust fan entrance filter, air filter, exhaust cyclone canceller, magnet, magnetic base, hopper suction gox for optional Europeanization. -

Uheat Preservating Hopper Dryer Machine

Blowing westernized hopper dryer, hopper made of stainless steel, equipped with “hot and blowing”, “cyclone exhause” function and double insulation barrel, especially suitable for collocation dehumidifier for drying engineering plastics, the loading capacity of the series is from 10-1200liters to 11types, The product is made of stainless steel except for parts contacting with raw materials. The 80 Liters above are equipped with a thermal cleaning door and provide weekly switch function.

-

Crusher Machine for Medical Products

Plastic grinding machine (Crusher Machine) adopts the imported special tool steel refining tool, the cutter clearance can be adjusted, and the cutter grinding can be repeated after blunt, and it is durable.

-

Plastic Mixer Machine for Efficient Mixing

Specification:

The barrel and the mixing leaf of mixer machine are made of all stainless steel. It is easy to clean, no pollution, automatic stop device, and can be set for 0-15 minutes to stop automatically.

Both mixing pail and vane are made of stainless steel, easy to clean and absolutely no pollution. The chain safety device can protect the safety of operator and machine. The material is thick, strong and durable, Well-distributed mixing can be done in a shot time, low energy consumption and high efficiency. Time setting can be controlled easily and precisely in the range of 0-15 minutes. Material outlet amounted manual discharging board, convenient for discharging. Machine feet welt with machine body, a firm structure. The standing color mixer can be equipped universal feet wheel and brake, convenient for moving. -

Mold Temperature Control Machine

Specification:

Voltage: 380V,

Frequency: 50HZ,

Heat Capacity: 6KW,

Maximum flow: 30L/min

Maximum Pressure: 3.5bar

Max Temperature: 95℃

Cooling Method : Water

Machine size: 85*35*65cm -

Plastic Loader Machine: Top Solutions for Your Business

Specification:

Voltage: 380V,

Frequency: 50HZ,

Power: 1110W

Capacity: 200~300kgs/hr;

Volume of material Hopper: 7.5L,

main body: 68*37*50cm,

Material Hopper: 43*44*30cm -

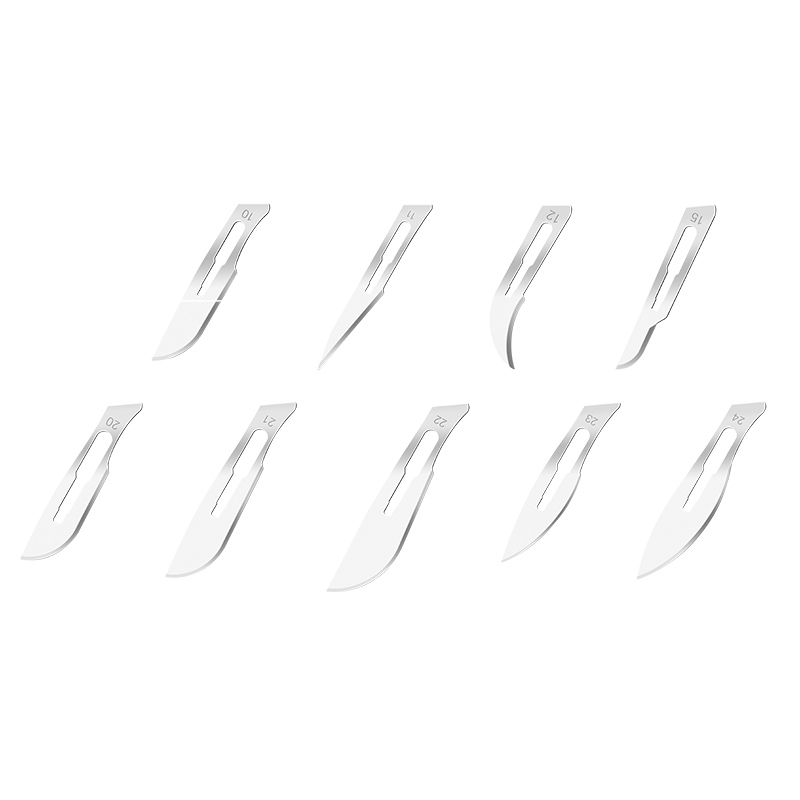

Surgical Blades: Find the Best Options

Specifications and models:

10#,10-1#, 11#, 12#, 13#, 14#, 15#, 15-1#, 16#, 18#, 19#, 20#, 21#, 22#, 23#, 24#, 25#, 36#

How to use:

1. Select a blade with appropriate specifications

2. Sterilize the blade and handle

3. Install the blade on the handle and start using it

Note:

1. Surgical blades are operated by trained medical personnel

2. Do not use surgical blades to cut hard tissue

3. The packaging is damaged, or the surgical blade is found to be broken

4. The products after use should be disposed of as medical waste to avoid cross-reuse -

High-Quality Surgical Scalpel for Precision Surgery

Specifications and models:

10#, 10-1#, 11#, 12#, 13#, 14#, 15#, 15-1#, 16#, 18#, 19#, 20#, 21#, 22#, 23#, 24#, 25#, 36#

How to use:

1. Select a blade with appropriate specifications

2. Sterilize the blade and handle

3. Install the blade on the handle and start using it

Note:

1. Surgical Scalpel are operated by trained medical personnel

2. Do not use surgical scalpel to cut hard tissue

3. The packaging is damaged, or the surgical scalpel is found to be broken

4. The products after use should be disposed of as medical waste to avoid cross-reuse