-

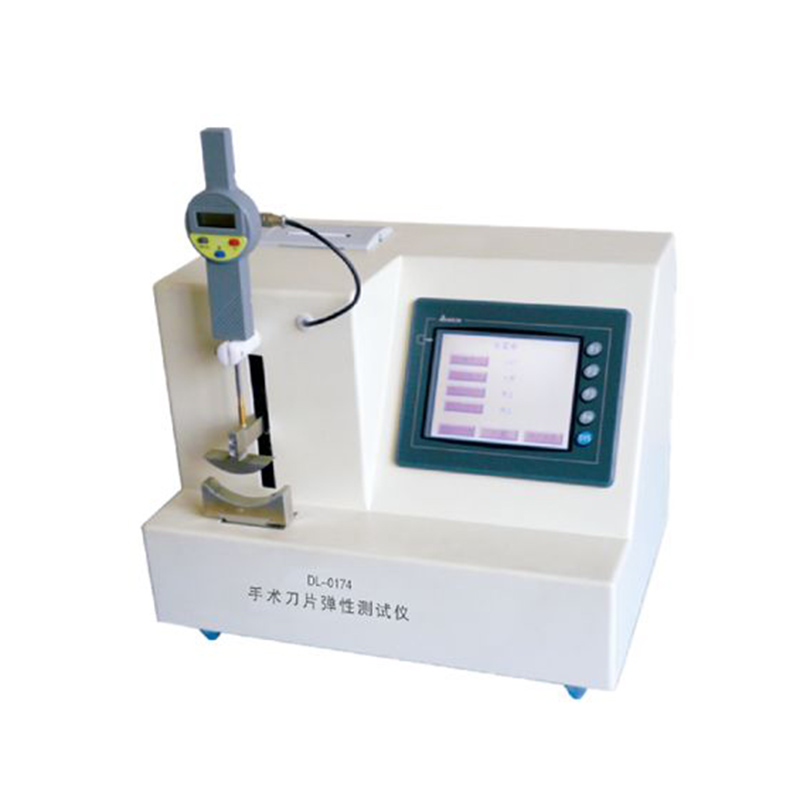

DL-0174 Surgical Blade Elasticity Tester

The tester is designed and manufactured according to YY0174-2005 “Scalpel blade”. Main principle is as follows: apply a certain force to the centre of the blade until a special column thrusts the blade to a specified angle; maintain it in this position for 10s. Remove the applied force and measure the amount of deformation.

It consists of PLC, touch screen, step motor, transmission unit, centimeter dial gauge, printer, etc. Both product specification and column travel are settable. Column travel, time of testing and the amount of deformation can be displayed on the touch screen, and all of them can be printed by the built-in printer.

Column travel: 0~50mm; resolution: 0.01mm

Error of deformation amount: within ±0.04mm -

FG-A Suture Diameter Gauge tester

Technical Parameters:

Minimum graduation: 0.001mm

Diameter of presser foot: 10mm~15mm

Presser foot load on the suture: 90g~210g

The gauge is used for determining the diameter of sutures. -

FQ-A Suture Needle Cutting Force Tester

The tester consists of PLC, touch screen, load sensor, force measuring unit, transmission unit, printer, etc. Operators can set parameters on the touch screen. The apparatus can run the test automatically and display the maximum and mean value of cutting force in real time. And it can automatically judge whether the needle is eligible or not. The built-in printer can print the test report.

Load capacity (of cutting force): 0~30N; error≤0.3N; resolution: 0.01N

Test speed ≤0.098N/s -

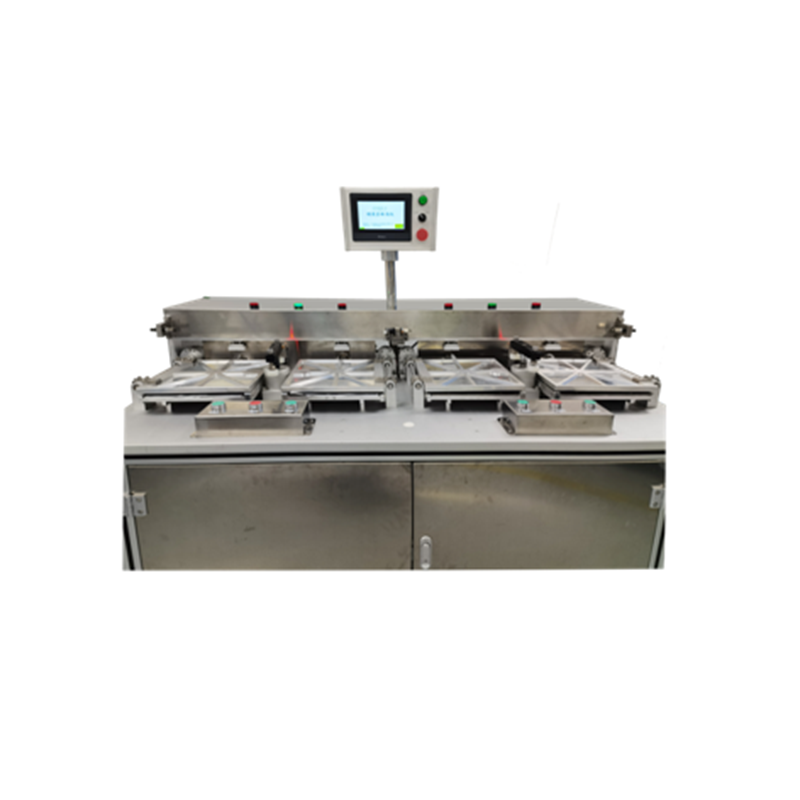

MF-A Blister Pack Leak Tester

The tester is applied in the pharmaceutical and food industries for checking air-tightness of packages (i.e. blisters, injection vials, etc. ) under negative pressure.

Negative pressure test: -100kPa~-50kPa; resolution: -0.1kPa;

Error: within ±2.5% of reading

Duration: 5s~99.9s; error: within ±1s -

NM-0613 Leak Tester for Empty Plastics Container

The tester is designed according to GB 14232.1-2004 (idt ISO 3826-1:2003 Plastics collapsible containers for human blood and blood components – Part 1: Conventional containers) and YY0613-2007 “Blood components separation sets for single use, centrifuge bag type”. It applies an internal air pressure to the plastics container (i.e blood bags, infusion bags, tubes, etc.) for air leakage test. In use of absolute pressure transmitter matched with secondary meter, it has advantages of constant pressure, high precision, clear display and easy handling.

Positive pressure output: settable from 15kPa to 50kPa above local atmospheric pressure; with LED digital display: error: within ±2% of reading. -

RQ868-A Medical Material Heat Seal Strength Tester

The tester is designed and manufactured according to EN868-5 “Packaging materials and systems for medical devices which are to be sterilized—Part 5: Heat and self-sealable pouches and reels of paper and plastic film construction—Requirements and test methods”. It is used for determining the strength of the heat seal joint for pouches and reel material.

Itconsists of PLC, touch screen, transmission unit, step motor, sensor, jaw, printer, etc. Operators can choose the needed option, set each parameter, and start the test on the touch screen. The tester can record the maximum and average heat seal strength and from the curve of the heat seal strentgth of each test piece in N per 15mm width. The built-in printer can print the test report.

Peeling force: 0~50N; resolution: 0.01N; error: within ±2% of reading

Separation rate: 200mm/min, 250 mm/min and 300mm/min; error: within ±5% of reading -

WM-0613 Plastic Container Burst and Seal Strength Tester

The tester is designed according to GB 14232.1-2004 (idt ISO 3826-1:2003 Plastics collapsible containers for human blood and blood components – Part 1: Conventional containers) and YY0613-2007 “Blood components separation sets for single use, centrifuge bag type”. It uses transmission unit to squeeze the plastics container (i.e. blood bags, infusion bags, etc. ) between two plates for lquid leakage test and digitally displays the value of pressure, so it has advantages of constant pressure, high precision, clear display and easy handling.

Range of negative pressure: settable from 15kPa to 50kPa above local atmospheric pressure; with LED digital display; error: within±2% of reading. -

Pump Line Performance Detector

Style: FD-1

The tester is designed and manufacturer according to YY0267-2016 5.5.10 <<Hemodialysis and Hemopurification Device External Circle Blood Line>> It applies external blood line examination1)、Flow range at 50ml/min ~ 600ml/min

2)、Accuracy: 0.2%

3)、Negative pressure range: -33.3kPa-0kPa;

4)、High precise mass flowmeter installed;

5)、Thermostatic water bath installed;

6)、Keep constant negative pressure

7)、Testing result automatically printed

8)、Real-time display for error range -

Waste Liquid Bag Leakage Detector

Style: CYDJLY

1)Differential Pressure Transducer: accuracy±0.07%FS RSS,, Measurement accuracy±1Pa, but ±2Pa when below 50Pa;

Min. Display:0.1Pa;

Display range: ±500 Pa;

Transducer range: ±500 Pa;

Max. pressure resistance on one side of the transducer: 0.7MPa.

2)Leakage rate display range: 0.0Pa~±500.0Pa

3)Leakage rate limitation: 0.0Pa~ ±500.0Pa

4)Pressure transducer: transducer range: 0-100kPa,Accuracy ±0.3%FS

5)Channels: 20(0-19)

6)Time: Set range:0.0s to 999.9s. -

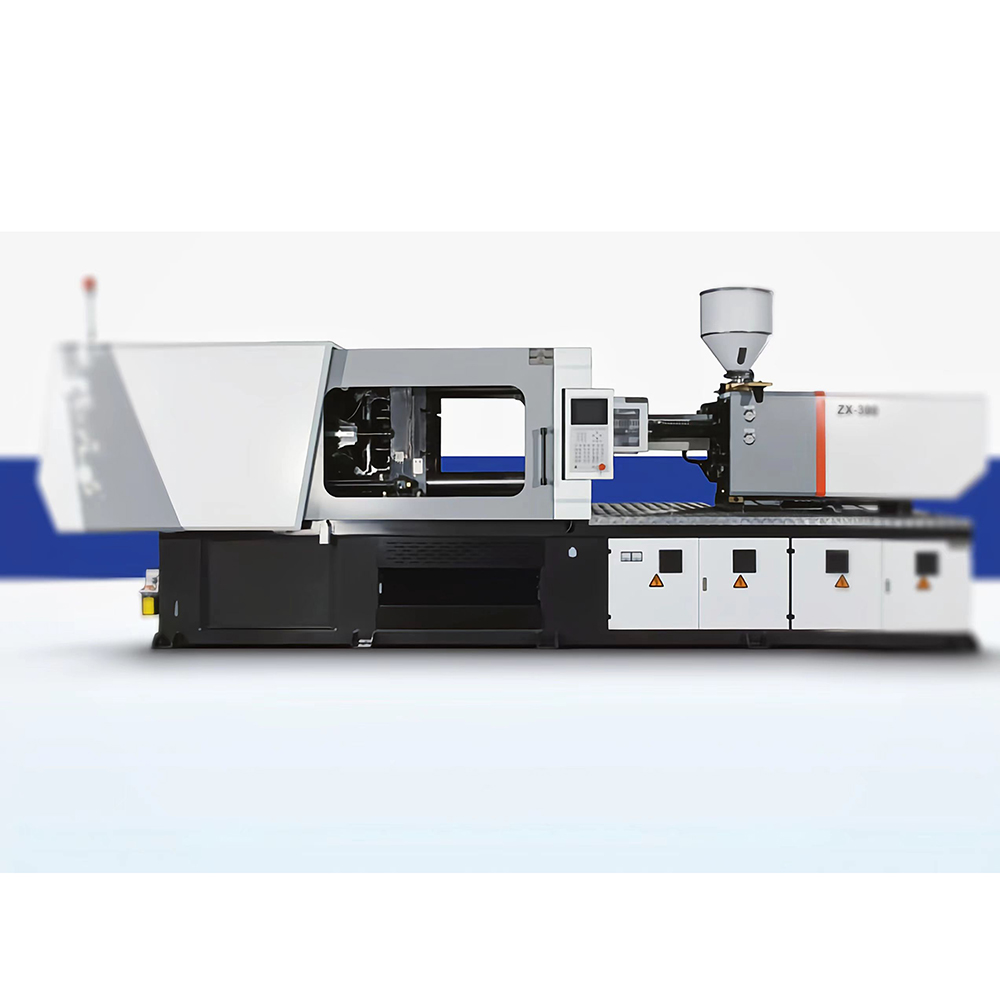

Revolutionize Your Manufacturing Process with Our Cutting-Edge Plastic Injection Machine!

Model unit GT2-LS90 GT2-LS120 GT2-LS160 GT2-LS200 GT2-LS260 GT2-LS320 GT2-LS380 International size rating 900-260 1200-350 1200-350 1600-550 2000-725 2600-1280 3200-1680 3800-1980 INJECTION UNITS Screw Diameter mm 32 35 40 35 38 42 40 45 50 45 50 55 55 60 65 60 65 70 65 70 75 Theoretical shot volume cc 125 149 195 164 193 236 251 318 393 350 432 523 630 749 879 820 962 1116 1045 1212 1392 Theoretical Shot weight(PS) g 113 136 177 149 175 214 229 2... -

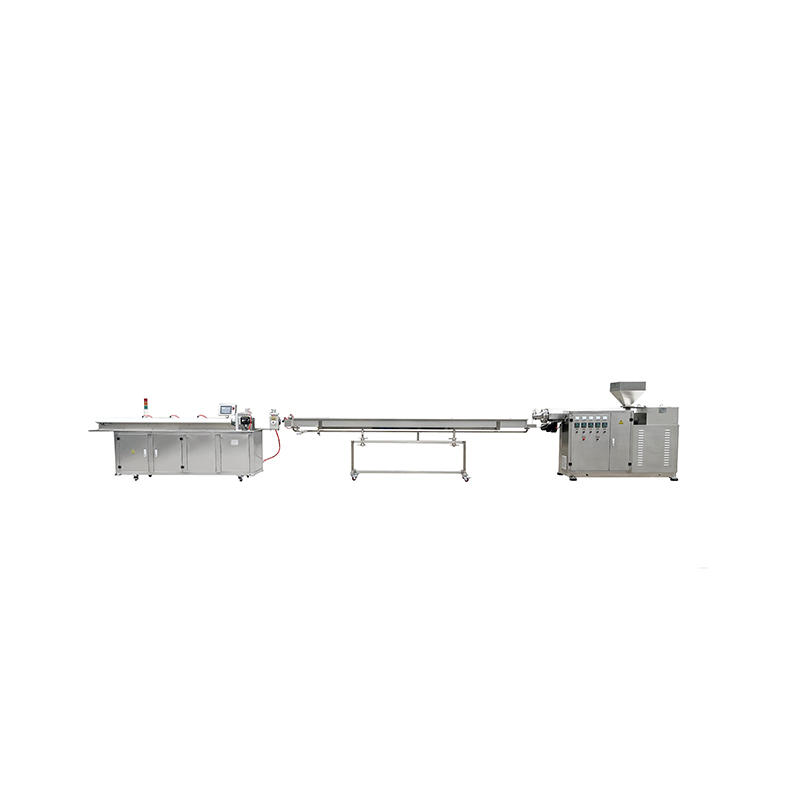

Extrusion Machine for Medical Products

Technical parameters: (1)Tube cutting diameter(mm): Ф1.7-Ф16 (2)Tube cutting length(mm): 10-2000 (3)Tube cutting speed: 30-80m/min(tube surface temperature under 20℃) (4)Tube cutting repeat precision: ≦±1-5mm (5)Tube cutting thickness: 0.3mm-2.5mm (6)Air flow: 0.4-0.8Kpa (7)Motor: 3KW (8)Size(mm): 3300*600*1450 (9)Weight(kg): 650 Automatic cutter parts list (standard) NAME MODEL BRAND FREQUENCY INVERTER DT SERIES MITSUBISHI PLC PROGRAMMABLE S7 SEIRES SIEMENS SERVO ... -

Gumming and Glueing Machine for Medical Products

Technical Details

1.Power adapter spec: AC220V/DC24V/2A

2.Applicable glue: cyclohexanone, UV glue

3.Gumming method: exterior coating and interior coating

4.Gumming depth: can be customized per customer requirement

5.Gumming spec.: Gumming spout can be customized (not standard).

6.Operational system: continuously working.

7.Gumming bottle: 250mlPlease pay attention when using

(1) The gluing machine should be placed smoothly and check whether the amount of glue is appropriate;

(2) Use in a safe environment, away from flammable and explosive materials, away from open flame sources, so as to avoid fire;

(3) After starting up every day, wait 1 minute before applying glue.