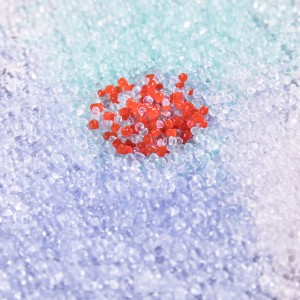

Medical Grade Compounds Non-DEHP series

We offer different NON-DEHP plasticizers according to customer's needs:

2.1 TOTM type

Widely used in blood transfusion (liquid) equipment category.

2.2 DINCH type

Concerning on the protection of red blood cells,more suitable for blood purification products.

2.3 DOTP type

Better plasticization,more cost-effective.

2.4 ATBC type,DINPtype,DOA type

Widely used in connection and suction tubes.

Non-DEHP PVC compounds are specialized formulations of polyvinyl chloride (PVC) that do not contain the plasticizer known as di(2-ethylhexyl) phthalate (DEHP). DEHP is commonly used as a plasticizer in PVC to improve its flexibility and durability. However, due to concerns about potential health risks associated with DEHP exposure, especially in certain medical applications, non-DEHP alternatives have been developed.Here are some key features and benefits of non-DEHP PVC compounds:DEHP-Free: Non-DEHP PVC compounds are free from di(2-ethylhexyl) phthalate, which is classified as a potential endocrine disruptor and can leach out of PVC products over time. By eliminating DEHP, these compounds offer a safer alternative for applications where DEHP exposure is a concern.Biocompatibility: Non-DEHP PVC compounds are typically formulated to be biocompatible, meaning that they have low toxicity and are suitable for contact with biological tissues and fluids. This ensures that the material is safe for patient use and minimizes the risk of adverse reactions.Flexibility and Durability: Non-DEHP PVC compounds are designed to provide the necessary flexibility and durability required for various applications. They offer similar mechanical properties to traditional PVC compounds, allowing for the production of flexible and long-lasting products.Chemical Resistance: These compounds are resistant to a wide range of chemicals, including cleaning agents and disinfectants commonly used in healthcare settings. This ensures that products made from non-DEHP PVC compounds can be effectively cleaned and sanitized without being damaged or degraded.Regulatory Compliance: Non-DEHP PVC compounds are formulated to comply with relevant regulatory standards and guidelines for medical devices and other applications. They are often tested and certified to meet biocompatibility and quality requirements, ensuring their suitability for use in various industries.Wide Range of Applications: Non-DEHP PVC compounds can be used in a variety of applications, including medical devices, pharmaceutical packaging, tubing, and other consumer products. They offer a versatile solution for industries looking to replace DEHP-containing PVC materials.Processing Compatibility: These compounds can be processed using standard PVC manufacturing techniques, such as extrusion, injection molding, and blow molding. They have good flow properties and can be shaped into the desired form, allowing for efficient production processes.Non-DEHP PVC compounds provide a safer alternative to traditional PVC materials containing DEHP, especially in applications where exposure to DEHP is a concern. They offer similar performance properties while minimizing potential health risks associated with DEHP exposure.