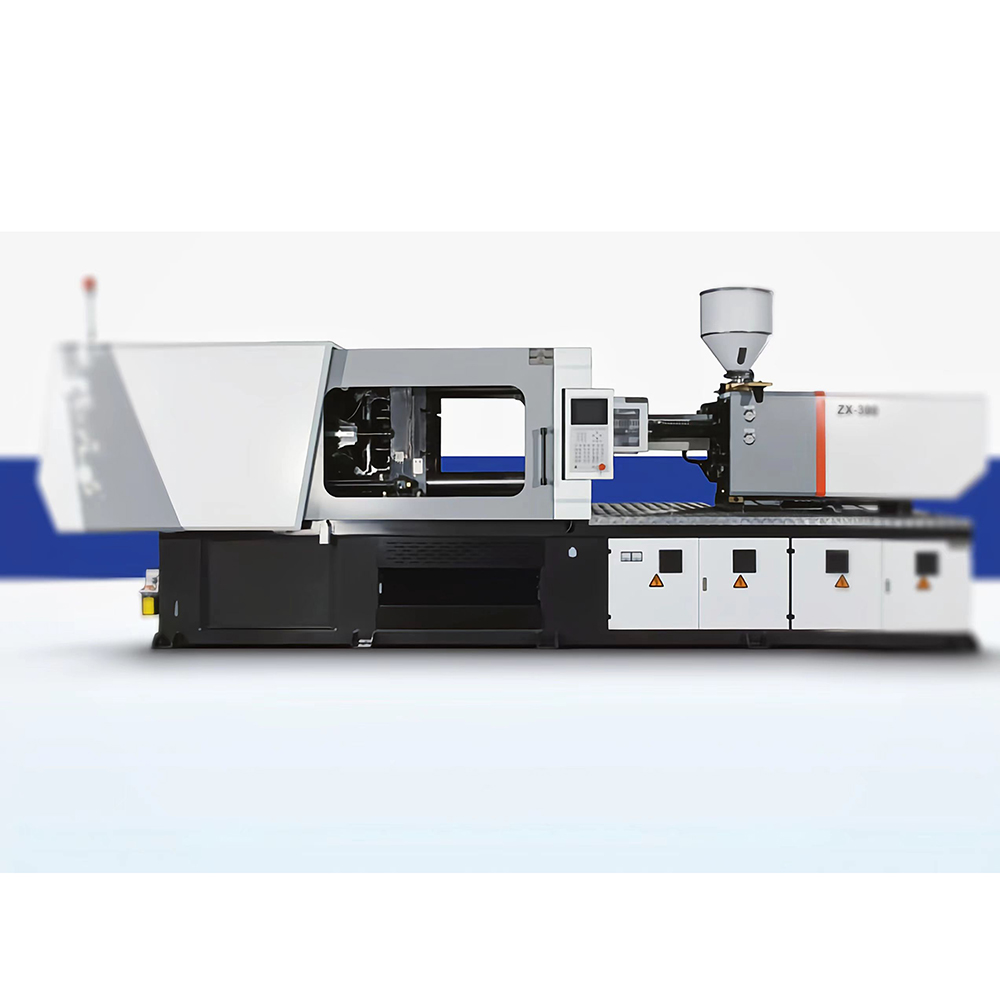

Revolutionize Your Manufacturing Process with Our Cutting-Edge Plastic Injection Machine!

| Model | unit | GT2-LS90 | GT2-LS120 | GT2-LS160 | GT2-LS200 | GT2-LS260 | GT2-LS320 | GT2-LS380 |

| International size rating | 900-260 | 1200-350 | 1200-350 | 1600-550 | 2000-725 | 2600-1280 | 3200-1680 | 3800-1980 |

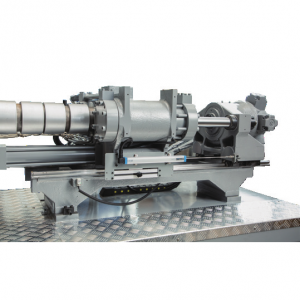

| INJECTION UNITS | ||||||||

| Screw Diameter | mm | 32 35 40 | 35 38 42 | 40 45 50 | 45 50 55 | 55 60 65 | 60 65 70 | 65 70 75 |

| Theoretical shot volume | cc | 125 149 195 | 164 193 236 | 251 318 393 | 350 432 523 | 630 749 879 | 820 962 1116 | 1045 1212 1392 |

| Theoretical Shot weight(PS) | g | 113 136 177 | 149 175 214 | 229 289 357 | 318 393 476 | 573 682 800 | 746 876 1016 | 951 1103 1266 |

| OZ | 4 4.8 6.3 | 5.3 6.2 7.6 | 8.1 10.2 12.6 | 11.2 13.9 16.8 | 20.2 24.1 28.2 | 26.3 30.9 35.8 | 33.6 38.9 44.7 | |

| Screw L:D ratio | L/D | 23 21 18.4 | 22.8 21 19 | 23.6 21 18.9 | 23.3 21 19.1 | 22.9 21 19.4 | 22.8 21 19.5 | 22.6 21 19.6 |

| Injection pressure | Mpa | 211 176 135 | 214 182 149 | 220 173 141 | 207 168 139 | 204 171 146 | 206 175 151 | 190 164 143 |

| Screw speed | rpm | 195 | 200 | 190 | 170 | 130 | 170 | 170 |

| Plasticizing capacity(PS) | kg/hr | 34 44 62 | 41 60 68 | 58 80 108 | 78 103 142 | 96 121 153 | 154 186 233 | 186 281 331 |

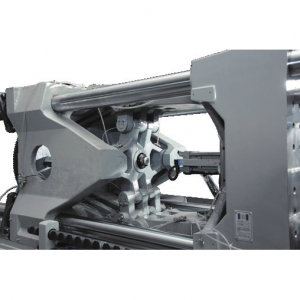

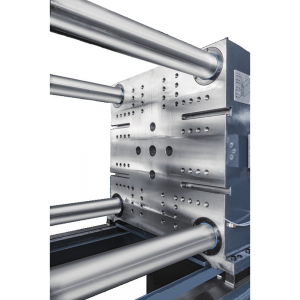

| CLAMPING UNIT | ||||||||

| Clamping force | KN | 900 | 1200 | 1600 | 2000 | 2600 | 3200 | 3800 |

| Max daylight | mm | 705 | 855 | 936 | 1010 | 1155 | 1250 | 1400 |

| Mould opening stroke | mm | 320 | 410 | 446 | 490 | 525 | 580 | 655 |

| Platen size | mm | 550 x 550 | 620 x 620 | 690 x 690 | 760 x 760 | 875 x 875 | 950 x 950 | 1060 x 1010 |

| Space between tie bar | 360 x 360 | 410 x 410 | 460 x 460 | 510 x 510 | 580 x 580 | 670 x 670 | 730 x 700 | |

| Mould thickness min/max | mm | 185~385 | 185~445 | 185~490 | 185~520 | 250~630 | 250~670 | 265~745 |

| Ejector force | KN | 31 | 42 | 42 | 49 | 67 | 77 | 111 |

| Ejector stroke | mm | 100 | 100 | 130 | 140 | 160 | 180 | 205 |

| Number of ejectors | unit | 4 + 1 | 4 + 1 | 4 + 1 | 4 + 1 | 12 + 1 | 12 + 1 | 12 + 1 |

| POWER/HEATING | ||||||||

| Pump motor | Kw | 11 | 11 | 15 | 18.5 | 22 | 30 | 37 |

| Hydraulic system pressure | MPA | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 |

| No of temp control zones | unit | 3+1 | 3+1 | 4+1 | 4+1 | 5+1 | 5+1 | 5+1 |

| Heating capacity | Kw | 6 | 7 | 8.8 | 13 | 15.4 | 19.3 | 23.2 |

| Weight | ton | 3 | 4 | 5 | 6.5 | 9.2 | 13.5 | 16.3 |

| Oil tank capacity | L | 220 | 270 | 345 | 425 | 530 | 565 | 665 |

| Dimensions | MxMxM | 4.08x1.14x1.87 | 4.5x1.23x1.91 | 5.05x1.3x1.95 | 5.5x1.36x2 | 6.3x1.54x2.07 | 6.92x1.67x2.2 | 7.7x1.77x2.2 |

Anesthesia and respiratory circuit PVC compounds refer to the specialized PVC materials used in the production of medical devices related to anesthesia and respiratory care. These compounds are formulated to meet the specific requirements and demands of these applications. Anesthesia PVC compounds are used in the manufacturing of various equipment used during anesthesia procedures, such as anesthesia masks, breathing bags, endotracheal tubes, and catheters. These compounds are designed to be flexible, yet sturdy, allowing for easy handling and manipulation during procedures. They are also formulated to be biocompatible, ensuring that they do not cause any adverse reactions when in contact with patient tissues or fluids. Respiratory circuit PVC compounds, on the other hand, are used in the production of respiratory therapy equipment, including ventilator tubing, oxygen masks, nebulizer kits, and breathing valves. These compounds must possess excellent flexibility and resistance to kinking, as they are often subject to repeated bending and twisting. They are also formulated to be compatible with the respiratory gases being delivered and should not contribute to additional resistance or hinder gas flow. Both anesthesia and respiratory circuit PVC compounds are designed with stringent quality control and adhere to medical industry standards and regulations to ensure safety and effectiveness. Manufacturers take into account factors such as biocompatibility, durability, resistance to chemicals and disinfectants, as well as ease of manufacturing. It is worth noting that while PVC has been commonly used in these applications due to its desirable properties, concerns have been raised regarding potential health and environmental impacts associated with the production, use, and disposal of PVC-based medical devices. Researchers and manufacturers are actively exploring alternative materials and technologies to address these concerns.In summary, anesthesia and respiratory circuit PVC compounds are specialized materials used in the production of medical devices for anesthesia and respiratory care. These compounds are carefully formulated to meet the specific requirements of their respective applications, ensuring safety, durability, and performance.