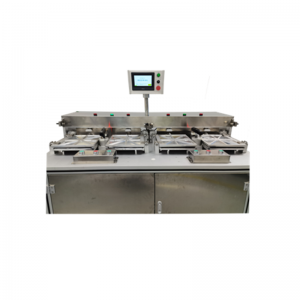

NM-0613 Leak Tester for Empty Plastics Container

A leak tester for empty plastic containers is a device used to identify any leaks or defects in the containers before they are filled with products. This type of tester is commonly used in industries such as food and beverage, cosmetics, and household chemicals.The testing process for empty plastic containers using a leak tester typically involves the following steps:Preparing the containers: Ensure that the containers are clean and free from any debris or contaminants.Placing the containers on the tester: Position the empty plastic containers on the test platform or chamber of the leak tester. Depending on the tester design, the containers may be manually loaded or automatically fed into the testing unit.Applying pressure or vacuum: The leak tester creates a pressure difference or vacuum within the test chamber, which enables the detection of leaks. This can be done by pressurizing the chamber or applying a vacuum, depending on the specific requirements and capabilities of the tester.Observing for leaks: The tester monitors the pressure change over a defined period of time. If there is a leak in any of the containers, the pressure will fluctuate, indicating a potential defect.Recording and analyzing results: The leak tester records the test results, including the pressure change, time, and any other relevant data. These results are then analyzed to determine the presence and severity of leaks in the empty plastic containers.The operating instructions and settings of a leak tester for empty plastic containers may vary depending on the manufacturer and model. It is important to refer to the user manual or guidelines provided by the manufacturer to ensure proper testing procedures and accurate results.By using a leak tester for empty plastic containers, manufacturers can check the quality and integrity of their containers, preventing any leakage or compromise of the products once they are filled. This helps minimize waste, maintain product quality, and meet industry regulations and standards.