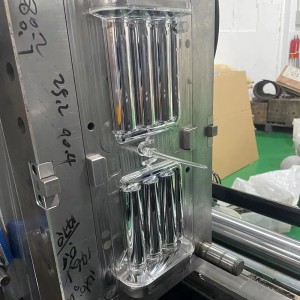

Nasal oxygen cannula mold/mould

A nasal oxygen cannula mold is a specialized tool used in the manufacturing of nasal oxygen cannulas. It is designed to create the shape and design of the cannula, ensuring consistency and precision in production. The mold is typically made from high-quality materials and crafted with attention to detail to accurately replicate the desired cannula shape.The manufacturing process involves injecting molten material, usually a medical-grade plastic, into the mold. Once the material cools and solidifies, the mold is opened, and the finished nasal oxygen cannula is removed. This mold ensures that every cannula produced is uniform in shape, size, and functionality.Nasal oxygen cannulas are commonly used in medical settings to deliver oxygen to patients through the nostrils. They are lightweight, flexible, and comfortable, allowing patients to receive oxygen therapy with ease.

|

1.R&D |

We receive customer 3D drawing or sample with details requirements |

|

2.Negotiation |

Confirm with clients details about: the cavity, runner, quality, price, material, delivery time, payment item, etc. |

|

3.Place an order |

According your clients design or chooses our suggestion design. |

|

4. Mould |

First We send mould design to customer approval before We make the mould and then start production. |

|

5. Sample |

If the first sample come out is not satisfied customer, we modify the mould and until meet customers satisfactory. |

|

6. Delivery time |

35~45days |

| Machine Name | Quantity ( pcs ) | The original country |

| CNC | 5 | Japan/Taiwan |

| EDM | 6 | Japan/China |

| EDM ( Mirror) | 2 | Japan |

| Wire Cutting ( fast ) | 8 | China |

| Wire Cutting ( Middle ) | 1 | China |

| Wire Cutting ( slow ) | 3 | Japan |

| Grinding | 5 | China |

| Drilling | 10 | China |

| Lather | 3 | China |

| Milling | 2 | China |