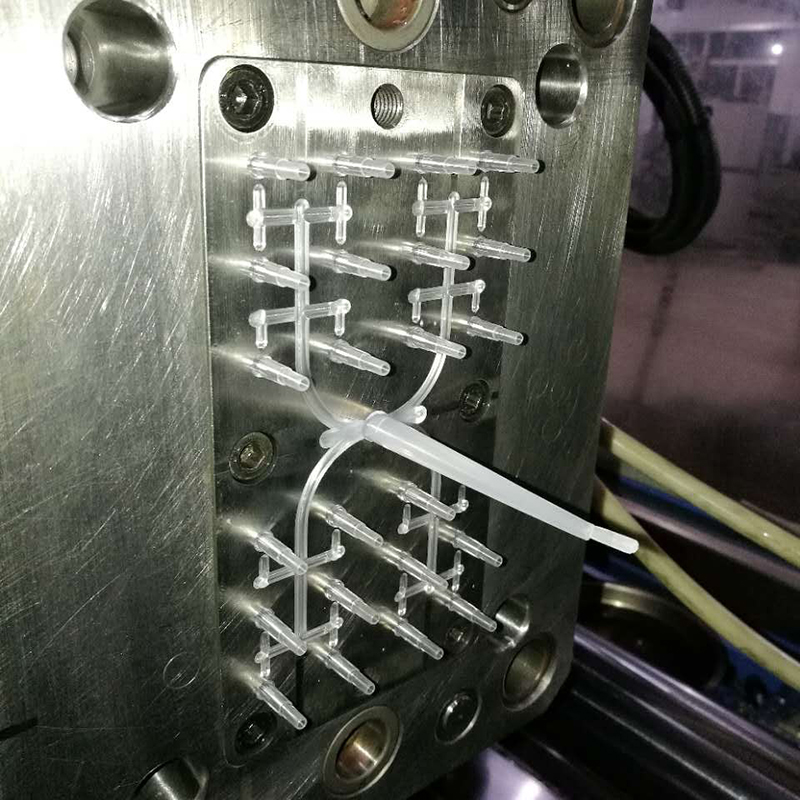

Medical hemodialysis Fistula Needle Mould

A fistula needle mold is a specialized tool used in the manufacturing of fistula needles. It is used to create the shape and design of the needle, ensuring accuracy and consistency in production. The mold is typically made from high-quality materials and precision-engineered to create smooth and efficient needle molds. The manufacturing process involves injecting molten material into the mold, allowing it to cool and harden, and then removing the molded needle from the mold. This tool plays a crucial role in the production of fistula needles, which are used for vascular access in medical procedures such as dialysis.

| 1.R&D | We receive customer 3D drawing or sample with details requirements |

| 2.Negotiation | Confirm with clients details about: the cavity, runner, quality, price, material, delivery time, payment item, etc. |

| 3.Place an order | According your clients design or chooses our suggestion design. |

| 4. Mould | First We send mould design to customer approval before We make the mould and then start production. |

| 5. Sample | If the first sample come out is not satisfied customer, we modify the mould and until meet customers satisfactory. |

| 6. Delivery time | 35~45days |

| Machine Name | Quantity ( pcs ) | The original country |

| CNC | 5 | Japan/Taiwan |

| EDM | 6 | Japan/China |

| EDM ( Mirror) | 2 | Japan |

| Wire Cutting ( fast ) | 8 | China |

| Wire Cutting ( Middle ) | 1 | China |

| Wire Cutting ( slow ) | 3 | Japan |

| Grinding | 5 | China |

| Drilling | 10 | China |

| Lather | 3 | China |

| Milling | 2 | China |