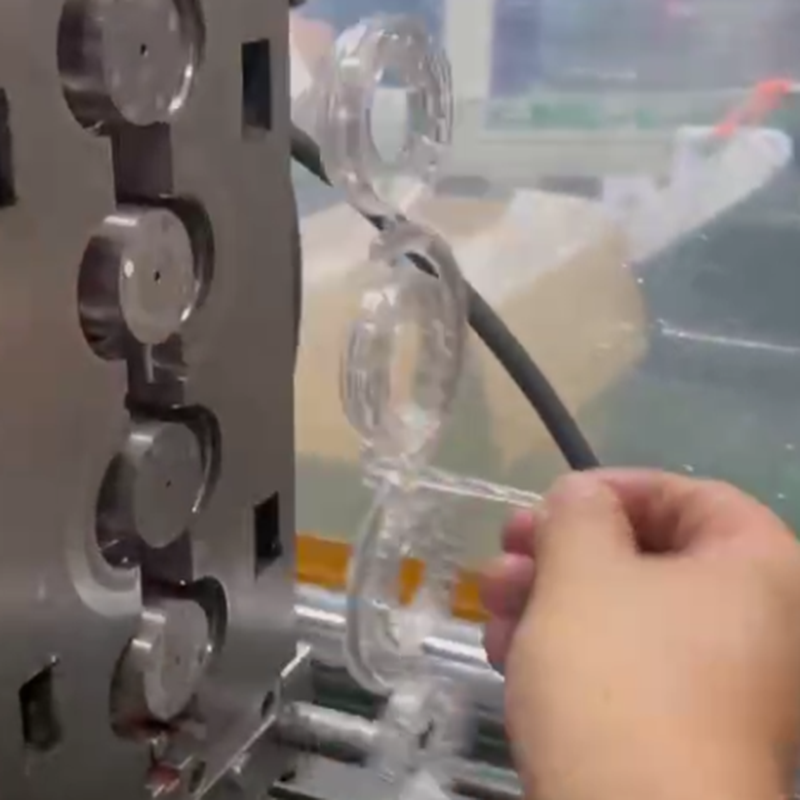

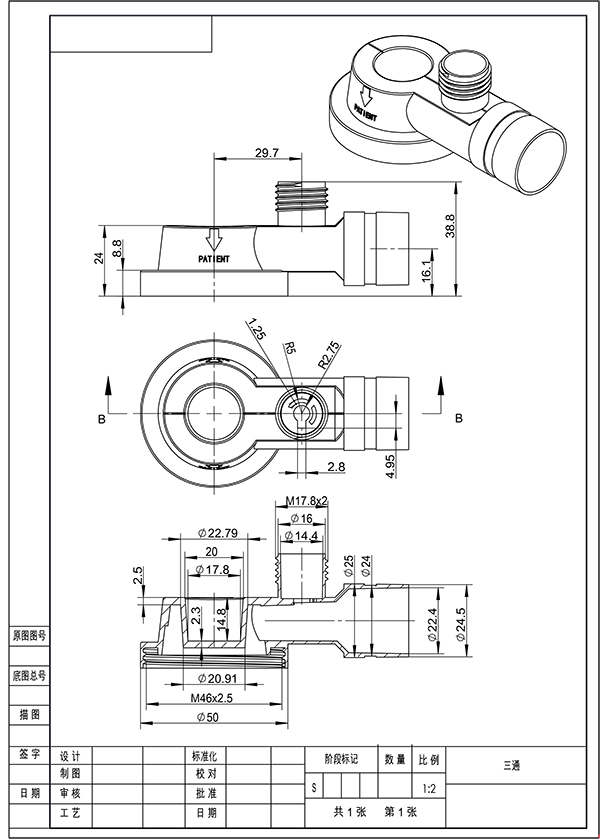

Emergency Manual Resuscitator plastic injection mold/mould

An emergency manual resuscitator, also known as an Ambu bag or bag-valve-mask (BVM) device, is a handheld device used in emergency medical situations to deliver positive pressure ventilation to a patient who is not breathing adequately or at all. It is commonly used when a patient's natural breathing or lung function is compromised, such as during cardiac arrest, respiratory failure, or trauma.The emergency manual resuscitator consists of a bag-shaped reservoir made of a collapsible material, usually silicone or latex, and a valve mechanism. The bag is connected to a face mask, which is securely placed over the patient's nose and mouth to create a seal. The valve mechanism allows for the control of airflow into the patient's lungs.Steps to use an emergency manual resuscitator:Ensure the mask is the correct size for the patient. There are different sizes available for adults, children, and infants.Position the patient on their back and ensure their airway is open. If necessary, perform manual airway maneuvers (such as head tilt-chin lift or jaw thrust) to open the airway.Squeeze the bag firmly to expel any residual air inside.Place the mask over the patient's nose and mouth, ensuring a secure seal.Hold the mask in place while using your other hand to squeeze the bag. This action will deliver positive pressure ventilation to the patient's lungs. The rate and depth of the breaths delivered will depend on the patient's condition and the guidance of medical professionals.Release the bag to allow the patient to exhale. Repeat the process according to the recommended frequency of breaths for the specific situation.It is important to coordinate the use of an emergency manual resuscitator with appropriate CPR techniques and in accordance with medical guidelines. Proper training and certification in resuscitation techniques are vital to ensure the correct use of this device and to provide life-saving care to patients in emergency situations.

| 1.R&D | We receive customer 3D drawing or sample with details requirements |

| 2.Negotiation | Confirm with clients details about: the cavity, runner, quality, price, material, delivery time, payment item, etc. |

| 3.Place an order | According your clients design or chooses our suggestion design. |

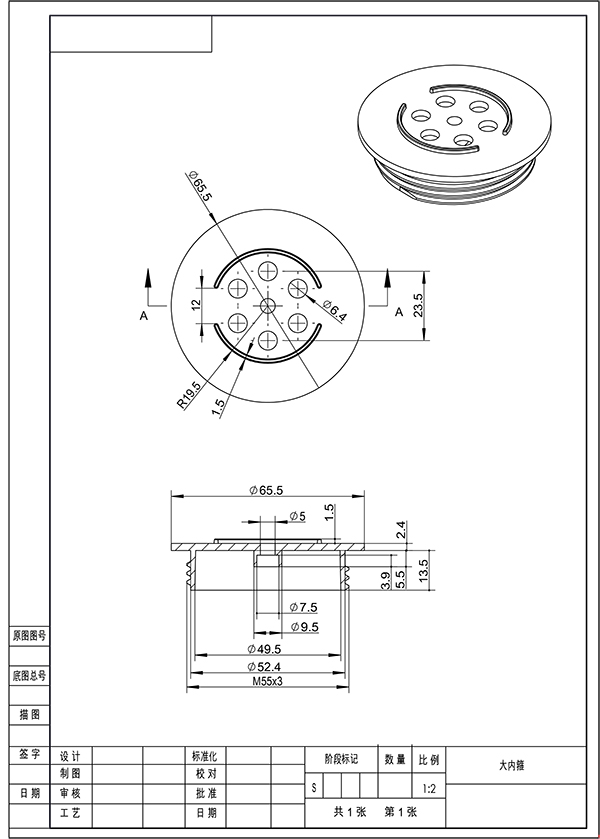

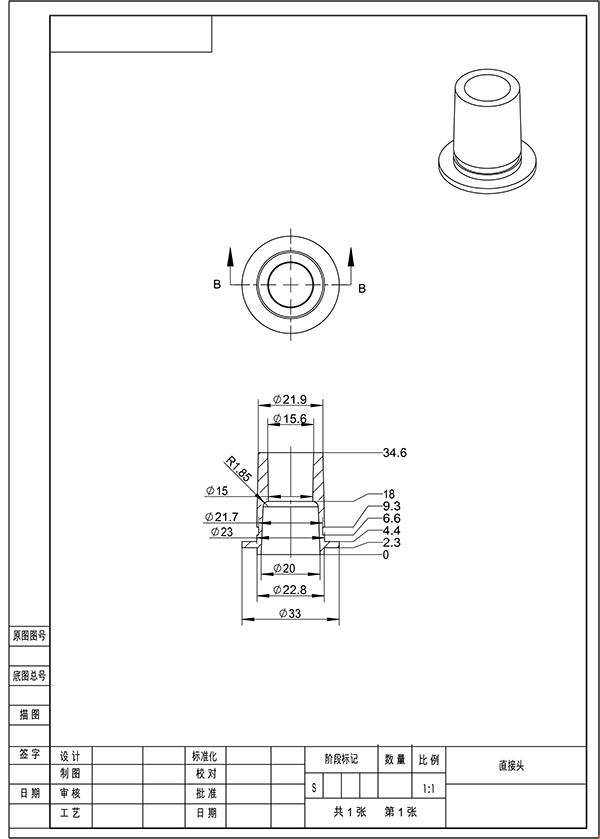

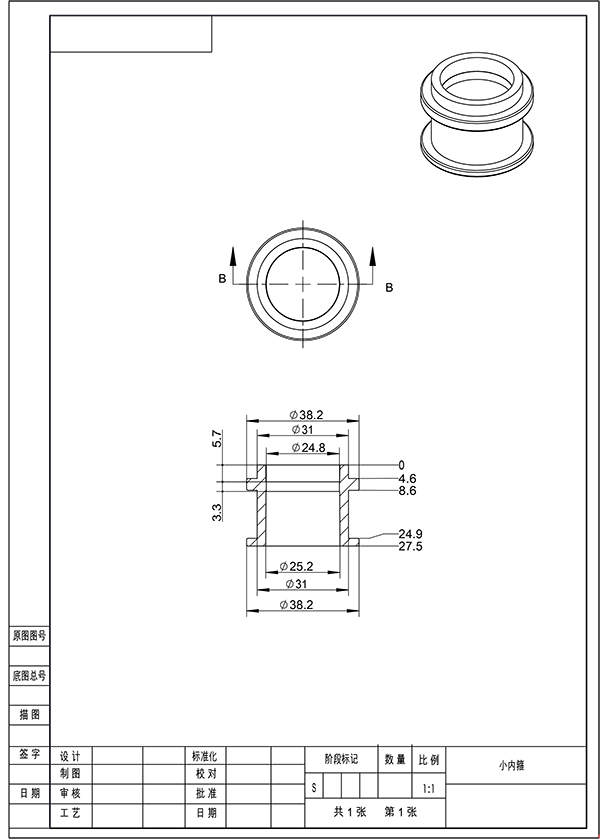

| 4. Mould | First We send mould design to customer approval before We make the mould and then start production. |

| 5. Sample | If the first sample come out is not satisfied customer, we modify the mould and until meet customers satisfactory. |

| 6. Delivery time | 35~45days |

| Machine Name | Quantity ( pcs ) | The original country |

| CNC | 5 | Japan/Taiwan |

| EDM | 6 | Japan/China |

| EDM ( Mirror) | 2 | Japan |

| Wire Cutting ( fast ) | 8 | China |

| Wire Cutting ( Middle ) | 1 | China |

| Wire Cutting ( slow ) | 3 | Japan |

| Grinding | 5 | China |

| Drilling | 10 | China |

| Lather | 3 | China |

| Milling | 2 | China |