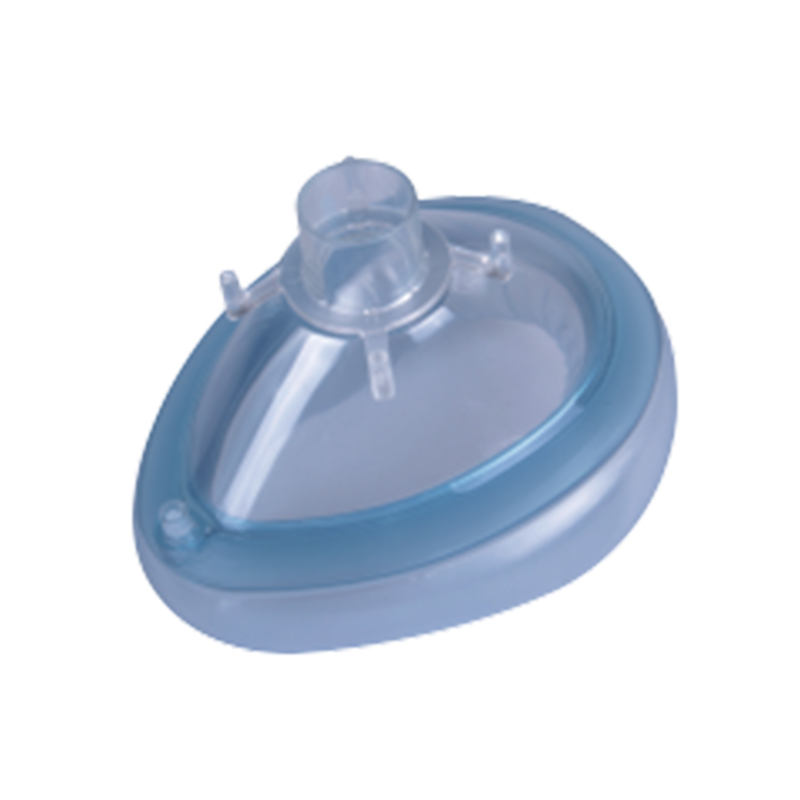

Anaesthesia Mask plastic injection mold/mould

An anesthesia mask, also known as a face mask, is a medical device used during anesthesia administration to deliver anesthetic gases to a patient. It covers the nose and mouth of the patient and is securely attached to their face, creating a seal.The anesthesia mask is connected to an anesthesia machine or a breathing circuit, which delivers a mixture of gases, including oxygen and anesthetic agents, to the patient. It ensures that the patient receives the necessary amount of oxygen and anesthetic agents during surgical or medical procedures while maintaining a patent airway.The mask is typically made of clear, soft, and flexible materials that can conform to the patient's face for comfort and effective sealing. It has an adjustable strap that goes around the back of the patient's head to keep the mask in place.Anesthesia masks come in different sizes to accommodate patients of various ages and sizes, ranging from infants to adults. Pediatric masks are available for small children and infants. Some masks may also have additional features such as an inflatable cuff to provide a better seal.The use of an anesthesia mask is a common method of administering anesthesia and is often used during induction of anesthesia, maintenance of anesthesia, and during recovery. It allows the anesthesiologist or anesthetist to closely monitor the patient's breathing, administer medications as needed, and make any necessary adjustments to ensure the patient's safety and comfort.It's important to note that the use of an anesthesia mask should be performed by qualified healthcare professionals who are trained in anesthesia administration. The proper selection and application of the mask are critical to ensure its effectiveness and the safety of the patient.

| 1.R&D | We receive customer 3D drawing or sample with details requirements |

| 2.Negotiation | Confirm with clients details about: the cavity, runner, quality, price, material, delivery time, payment item, etc. |

| 3.Place an order | According your clients design or chooses our suggestion design. |

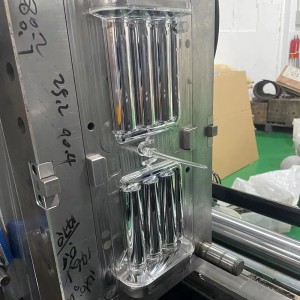

| 4. Mould | First We send mould design to customer approval before We make the mould and then start production. |

| 5. Sample | If the first sample come out is not satisfied customer, we modify the mould and until meet customers satisfactory. |

| 6. Delivery time | 35~45days |

| Machine Name | Quantity ( pcs ) | The original country |

| CNC | 5 | Japan/Taiwan |

| EDM | 6 | Japan/China |

| EDM ( Mirror) | 2 | Japan |

| Wire Cutting ( fast ) | 8 | China |

| Wire Cutting ( Middle ) | 1 | China |

| Wire Cutting ( slow ) | 3 | Japan |

| Grinding | 5 | China |

| Drilling | 10 | China |

| Lather | 3 | China |

| Milling | 2 | China |